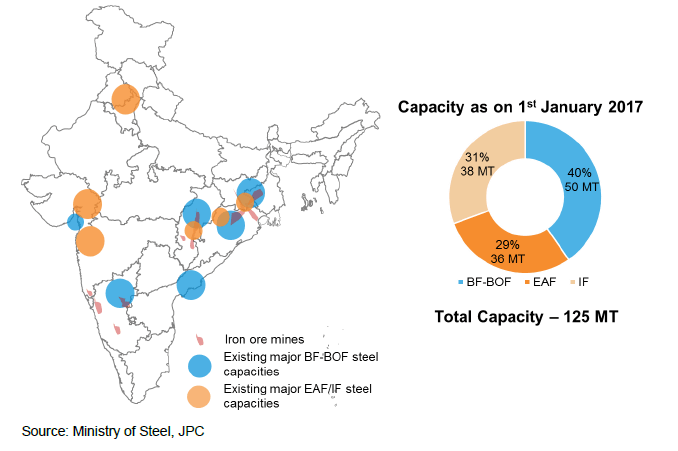

Indian Crude steel capacity is expected to be 300 million tonnes (MT)

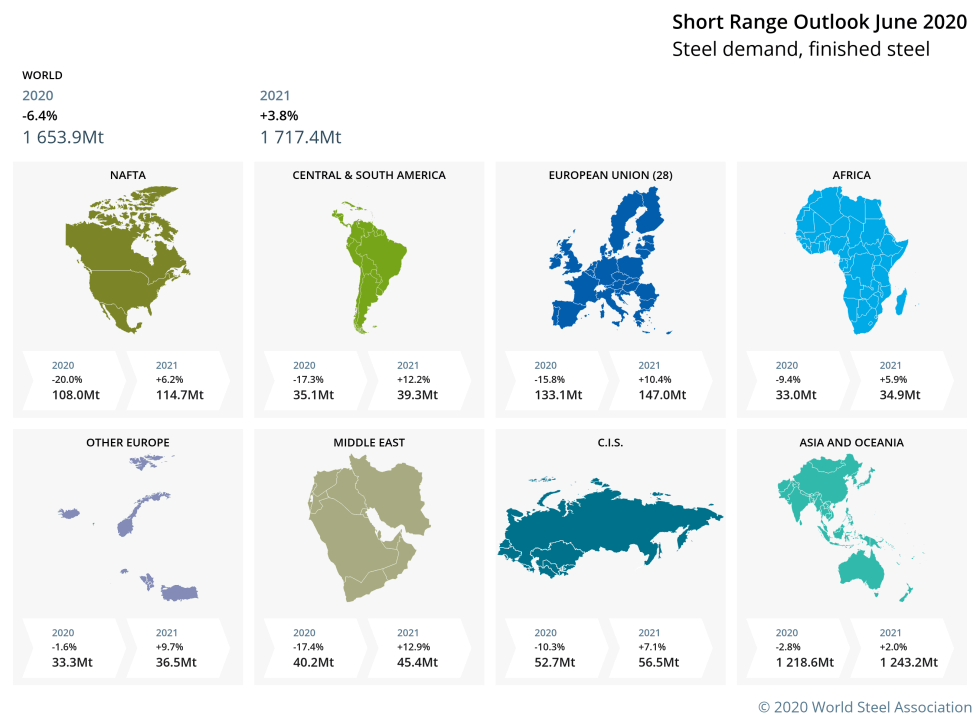

In the Short-Range Outlook (SRO) by The World Steel Association for 2021, steel demand is expected to recover to 1,717 Mt, an increase of 3.8 % over 2020.

India is at 2nd position among the largest steel producer in the world. Indian Crude steel capacity is expected to be 300 million tonnes (MT) in 2030-31 as envisaged in National Steel Policy 2017.